Valves

In CNC machining for industrial valves, various components are manufactured to ensure the proper functioning of the valves. Here are some common types of industrial valve components that often undergo CNC machining.

Gate Valves:

- It uses a sliding gate (disc or wedge) to control flow.

- Well-suited for on/off applications.

Ball Valves:

- Utilizes a rotating ball with a bore to control flow.

- Offers quick shut-off and is versatile.

Butterfly Valves:

- Features a disc mounted on a rotating shaft to control flow.

- Suitable for large flow applications.

Globe Valves:

- It uses a disc that moves up and down to control flow.

- Suitable for throttling applications and offers good control.

Check Valves:

- Allows flow in one direction only, preventing backflow.

- Common types include swing, lift, and ball check valves.

Plug Valves:

- Employs a cylindrical or conical plug to control flow.

- Suitable for applications where quick open/close is required.

Diaphragm Valves:

- It uses a flexible diaphragm to control flow.

- Suitable for handling corrosive or abrasive fluids.

Needle Valves:

- Features a slender, tapered point at the end of a valve stem.

- Offers precise flow control in low-flow applications.

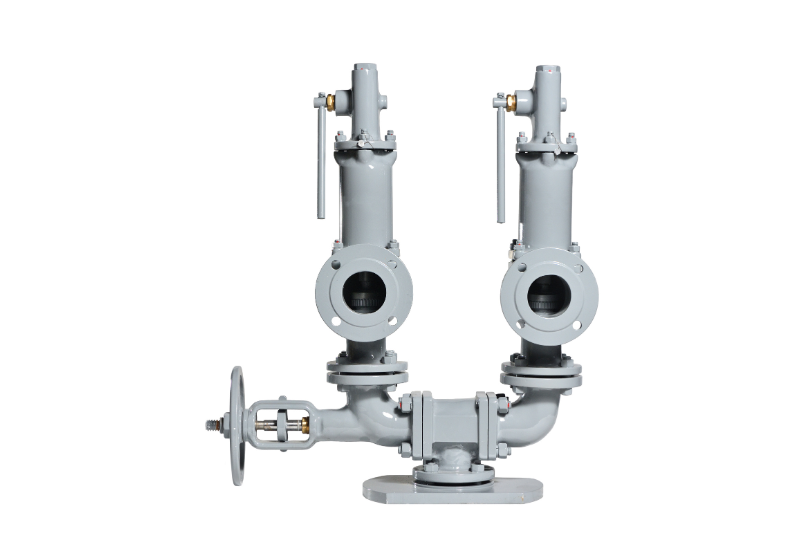

Pressure Relief Valves:

- Automatically releases pressure from a system when it exceeds a set limit.

- Ensures system safety.

Safety Valves:

- Similar to pressure relief valves, designed to protect equipment from overpressure.

Control Valves:

- Modulates the flow of fluid to control process conditions.

- It can include globe, butterfly, or ball valves with actuators.

Plug Valves:

- It uses a cylindrical or tapered plug to control flow.

- Suitable for applications with slurries and fluids with suspended solids.

Pinch Valves:

- Controls flow using a pinching mechanism on a flexible tube.

- Suitable for handling abrasive and corrosive materials.

Piston Valves:

- It uses a piston to control flow.

- Commonly used in steam and water applications.

Knife Gate Valves:

- Utilizes a sharp-edged gate to cut through and control flow.

- Suitable for handling viscous fluids and slurries.

Ball Check Valves:

- A type of check valve with a ball that moves to allow or block flow.

Foot Valves:

- Installed at the bottom of a pump suction line to prevent backflow.

Float Valves:

- Controls the level of a liquid by using a float to open or close the valve.

The selection of a specific valve type depends on factors such as the application, flow requirements, pressure conditions, and the nature of the fluid being handled. CNC machining is crucial in the production of these components as it allows for high precision, consistency, and the ability to work with a variety of materials. The accuracy achieved through CNC machining ensures that the valves meet stringent quality standards and perform reliably in industrial applications.

We are a leading engineering organisation engaged in the manufacturing of precision components, where Quality is at the heart of every aspect of each component that we make at the benchmark of reliability.

Industry We Serve

Quick Links

Contact Us

Address:

SF. No. 329/4, Pappampatti Main Road,

Kannampalayam, Sulur, Irugur,

Coimbatore, Tamil Nadu, 641402

GSTIN: 33AABCZ4485C1ZE

CIN: U29222TZ2019PTC032952 Phone:+91 95007 00002

Email: Books@2degrees.co.in

Working Hours: 24/7